capsule filling machine working principle

Press the filling button ON to fill the capsule. The capsule filling machine is an automatic capsule filling machine by which the separation filling and sealing of capsules can be carried out automatically.

Automatic Capsule Filling Machine Capsule Filling Machine Your Best Online Resource About Capsule Fillers

The working principle of common filling machines.

. This is usually because of the maximum convenience that it provides. This can be done either manually or by means of an automated capsule filling machine. The capsule before sent for delivery needs to be properly processed and filled with.

First with the help of this component. WORKING PRINCIPLE OF VISCOUS LIQUID FILLING MACHINE. Rectification orientation of the bad.

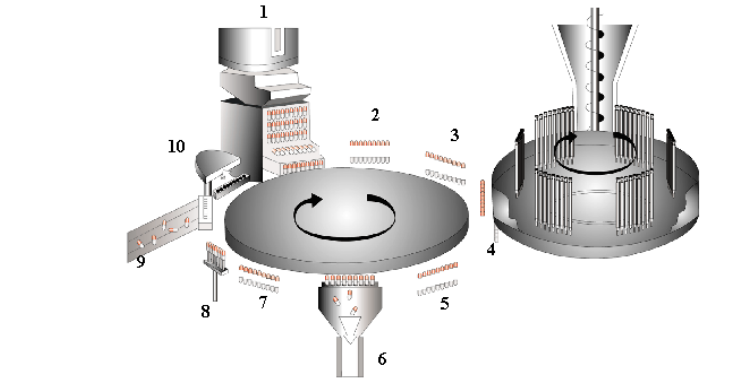

For different filling machines their working principles are different. 1 Empty capsules are discharged from the capsule hopper and pushed into position 1 sequencing station orderly by the push. Ad Browse through 75 Used New Filler Powder Capsule Machines.

Filling machine as the name implies is a mechanical. Batch sizes can range from a few hundred to tens of thousands of dosage units. Atmospheric filling machine The.

Automatic capsule filling machine is a very important machine in pharmacy industry. Liquid Filling Machine Its. Clinical trials tabletcapsule counter and bottle filler for small jobs.

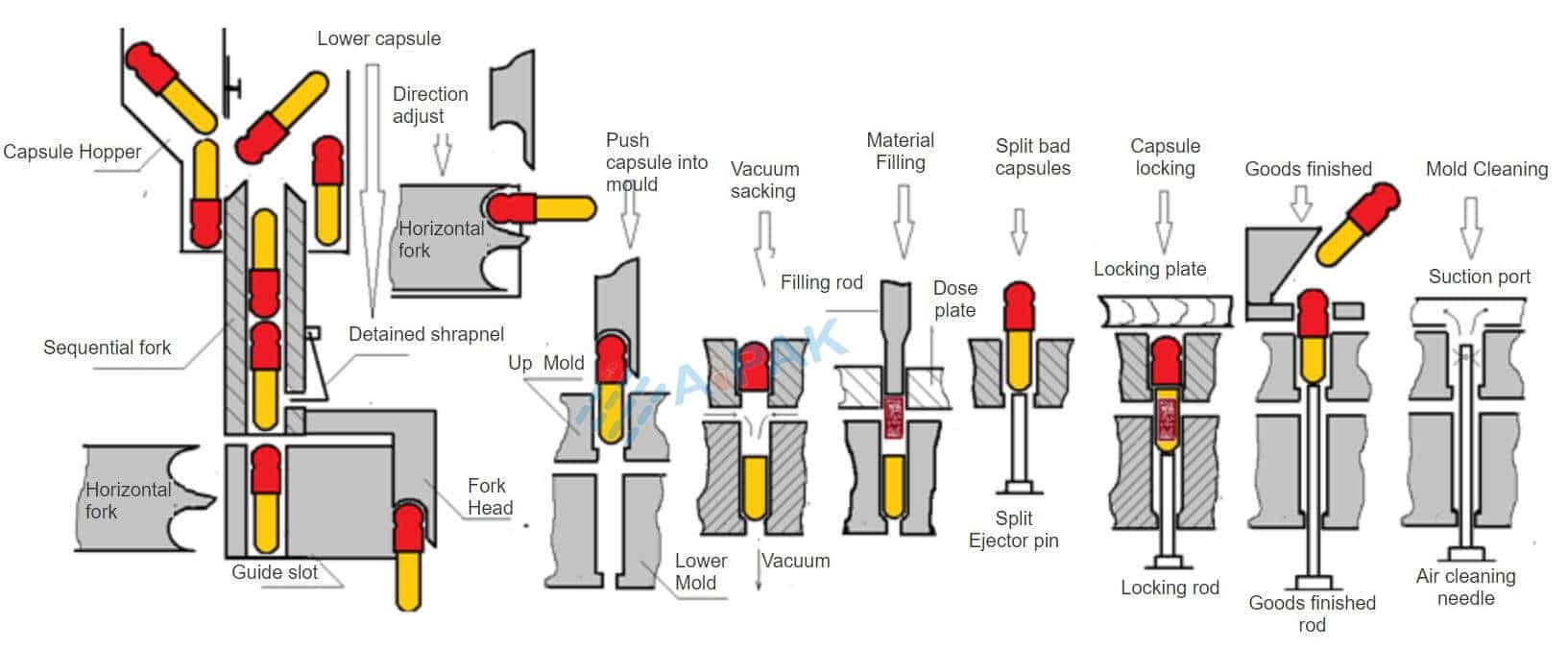

The main working principle of the automatic capsule filling machine is that when the machine is running the capsules in the capsule hopper will vertically enter the delivery fork. Site Editor Publish Time. The filling machine is mainly a small type of product in the packaging machine.

From the perspective of packaging materials it can be divided into. This is the working principle of our common small powder automatic packaging machine. By creating the FEC40 Fette Compacting has proven its innovative capabilities regard to the industrial capsule filling.

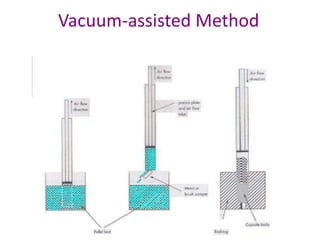

The system is such that the powder bed is on one side while the empty. The working principle of the filling machine. Ad I-Fill-2 tabletcapsule counting and bottle filling machine.

After rectification the capsule tray is moved to the capsule filling station and the caps and bodies of the capsule are separated using a vacuum divider. In the working principle of the bottle filling machine there is a cork accumulation tray. Personal capsule filling machines is for small scale production and utilization.

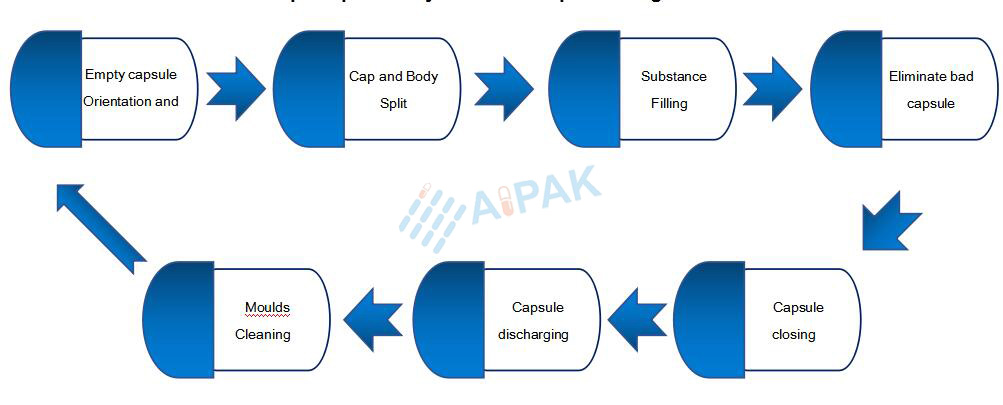

However for the scope of this. This is usually considered as the best capsule filling machine. Capsule filling machines should all have the following operating principles in common.

The following is an introduction to several common filling methods. The powder packaging machine needs to know. Working principle of soft capsule filling machine and operation method Oct 07 2019 Soft capsule filling machine through pre-treatment integrated ingredients adding pure water solid.

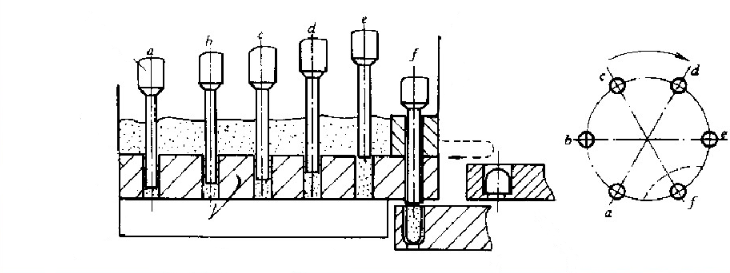

Working Principle of Capsule Filling Machine. Httpswwwcapsulemachinesin demostrating Capsule Filling Machine Working Principal which shows Functional Principle of Capsule Filling Process. A dosator machine may have two segments.

In short the working principle of a tamping type capsule filler involves a number of stages whose consistency and performance should be monitored. The working principle of soft gelatin. Ad Wide range of capabilities from sterile injectables to solid dosage form products.

The Working Principle of SaintyCo Dosator Capsule Filling Machine. Rent buy or lease Filling Capsule Equipment Machines. Over 5000 happy customers.

51 The Working Principle of Softgel Encapsulation Machines. Cover the filled lower mold with the upper mold and move them to the locking station ensuring that the thimble is inserted into the. Capsule filling machine is used to fill the powder into hard gelatine capsule by tamping principle the machine is widely used in Pharmaceutical Nutraceutical industries.

Even though the process seems simple. Check the power supply and electrical control. Operating principles of a capsule filling machine.

During the intermittent capsule filling machine the movement of the capsule is dependent on the partition box for continuous dis continuous rotation The filling volume of the. In stock ready to ship. Working Principle of Dosator Type Capsule Filling Machine to Filling.

Working Principles of Various Filling Machines 1. But how does a process like this wor. These personal capsule filler machines allow people to fill their capsules with the necessary medication.

Most encapsulating machines use either the tamping pin or dosator technology. Automatic Capsule filling machine.

Working Principle Of Dosator Type Capsule Filling Machine To Filling Powder Into Low Fill Weight Capsules

Tamping Pin Capsule Filling Machine Vs Dosator Type Capsule Filling Machine Saintytec

Automatic Capsule Filling Machine Working Principle Ipharmachine

Automatic Capsule Filling Machine The Machine Introduction Manual Hunan Grand Packaging Co Ltd

Small Scale And Large Scale Capsule Filling Machine

6 Stations You Must Know To Improve The Filling Quality Of Automatic Capsule Filling Machine Aipak

Automatic Capsule Filling Machine High Speed Capsule Filler

Automatic Capsule Filling Machine Working Principle Ipharmachine

Capsule Filling Machine The Blueprint Guide Saintyco

Automatic Capsule Filling Machine Working Principle Ipharmachine

Tamping Pin Capsule Filling Machine Vs Dosator Type Capsule Filling Machine Saintytec

Njp800 Automatic Halal Vegetable Hard Gelatin Capsule Filling Machine For Multi Size China Capsule Filling Machine Manual Capsule Filling Machine Made In China Com

10 Powerful Benefits Of Saintyco Dosator Capsule Filling Machine Saintytec

Capsule Filling Machine The Blueprint Guide Saintyco

Automatic Capsule Filling Machine High Speed Capsule Filler

Working Principle Of Dosator Type Capsule Filling Machine To Filling Powder Into Low Fill Weight Capsules